Apr 22, 2012 admin

On what evidence did Mr. Gaddis base his “new blade forgings” statement on?

The following is from the Oct 95 RKS Newsletter:

Stidham: Springfield Randall Update

On November 3, 1994 I had a very interesting conversation with Gary Randall. Packard Larsen, the son of W.F. Larsen, had stopped by to see Gary at the Randall shop. W.F. Larsen as most of you know is the man that made the Springfield Randall’s in 1943 and 1944. Soon after this time “Bo” Randall lost contact with Mr. Larsen and very little is known about him after the war years.

It seems that Packard Larsen was reading the New York Times in December 1989 and read that “Bo” Randall had died. And wasn’t this the man his dad had been involved with in WWII and yes the Randall knife shop was still in business.Then in 1994, Packard Larsen, retired Air Force Colonel and son of W.F. Larsen, while visiting Orlando, stopped to see Gary and left his address and Gary was kind enough to make it possible for Janie and me to visit Pack Larsen in May of this year.

The life of Pack Larsen is an interesting story in itself. A very energetic 70 year old man full of life and very interesting to talk to, he enlisted in service in 1942 and graduated pilot school in 1949, after having crashed out in 1945. He served as a navigator in WWII.

His dad gave him a Springfield Randall, which he carried in WWII and on 111 missions in the Korean War. He also flew an F86 and was in the Vietnam War. On the back of his knife sheath he has written, “Lt. P. Larsen, AO 2089257, 35th FBS, APO 929.

But the main story here, to the Randall collector, is what happened to W.F. Larsen after WWII and who was he? Janie and I visited Mr. and Mrs. Packard Larsen May 18, 1995 and what you are about to read was made possible by the Larsen’s.

William Frederick Larsen was born on September 15, 1888 in Waupaca, Wisconsin. His father, a barrel maker, immigrated from Denmark in 1860.W.F. married Elizabeth Packard (a New York Shakespearian actress) in 1915 and she died in 1939. They had three children. He married Edith Clarke in 1941, she having two daughters from a previous marriage.W.F. was the general agent for Mutual Trust Life Insurance Company in Springfield, Massachusetts and then in 1941 he went into the theatrical supply business. Then when WWII started, movie and photo supplies stopped going to the public and went to the war effort. In 1943 W.F. Larsen somehow came up with the idea to make knives. In Bob Gaddis’s book, “Randall Made Knives: The History of the Man and the Blades”, you will find on pages 95-104 a detailed account of his involvement with “Bo” Randall. But Gaddis also states little is known of W.F. Larsen after the war years.

According to Gaddis, there is also some ambiguity about the forging of the Springfield Randall blades. When I asked Packard Larsen about this he offered the following. He remembers that his dad purchased a batch of World War I bayonets from the Springfield Armory. It seems that Russia had ordered several WWI bayonets after WWI and then was unable to receive the order due to a revolution in Russia. These bayonets were then purchased by W.F. Larsen in 1943 and he had them forged into Springfield Randall blades. This information is all very sketchy and recalled from 50 years of memory. Packard did say that one of his sisters would go to Northampton to pick up these blades occasionally. He also remembers his dad assembling some of these knives in the basement of their house in Springfield, Massachusetts. He remembers barrels of leather washers and his dad installing them on the knife handles himself. The knives were final finished in Northampton.

In 1945 W.F. Larsen sold his house in Springfield and moved to Florida. He purchased Gardner’s Motel on US I in Delray Beach, Florida. He and Edith ran Larsen’s Motel until he died in 1954.

Another interesting event occurred while doing research for this story. While visiting W.F. Larsen’s daughter and son-in-law in the Springfield area I was able to purchase a very historic knife. When I made the call for an interview appointment I was told, yes, they did have a Springfield Randall that Mr. Larsen had given his son-in-law. While there I purchased this knife, but it was not a Springfield Randall, but an Orlando made Randall in a mint Springfield sheath. On page 98 of Gaddis’s book he states that “Bo” Randall sent a complete knife to Larsen on May 20, 1943. I believe this is the knife that “Bo” sent Larsen as a pattern knife. ///////// Rhett Stidham

This early article by Rhett about Springfield Randall’s deserved another visit. More than a couple of these knives exist to this day. There has been several good articles/essays about Springfield’s written, as well as photographed examples of the various ‘types’ known published. When an example shows up, the discussion always seems to end up with the question, “Where was this one made?” This of course is questioning whether a particular example is a Northampton knife or something else i.e. finished in Larsen’s basement as rumored many were. I believe the information has been available all along to answer that question, and it may contradict some of things that have been written subsequently to the publication of Gaddis’ book.

According to Gaddis, the number of knives assembled and/or finished by NHC is at least 644, more than the previously thought number of 500 knives. Interesting that Gaddis also states the last 140 of those knives were delivered to Abercrombie & Fitch in January 1945! Gaddis also states that Larsen said he started “another batch” by the end of May, 1945. It seems that 444 were finished by some other entity prior to the involvement of Northampton Cutlery. What makes this pertinent, is that previous thought led one to believe that these knives of ‘lesser’ quality than the Northampton knives were made after the Northampton involvement. It appears now that the majority – 444 specimens – were made prior to the Northampton run, with around 250 after. So the net result is approximately half of Larsen’s Springfield run was touched by Northampton Cutlery in some fashion with the other half presumably by Larsen himself or a craftsman enlisted by Larsen to do so. Perhaps some Northampton employees were “moon lighting” the work and/or Northampton was allowing the use of its facilities after hours ‘off the record’, because it seems there are more of the Northampton quality around than the so-called ‘basement’ knives.

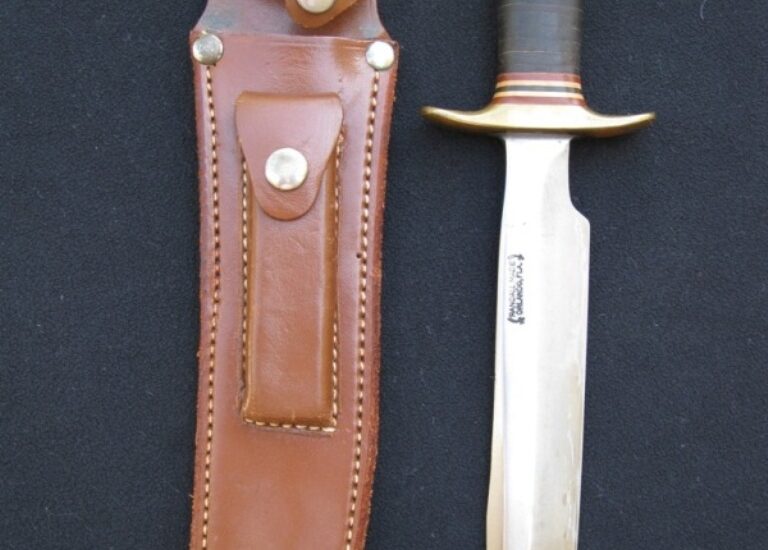

I wanted to offer some photographs of the knife Rhett acquired from Packard Larsen as told in the article from the October 1995 RKS newsletter. This is the actual knife that Larsen patterned his Springfield Randall from, a unique piece of Randall Made history. Note that the sheath is a Southern Saddlery sheath, not a Mosser as was stated in Rhett’s original article, nor a Heiser as stated by Gaddis. I think it is very evident which sheath was sent to Larsen by Bo, because the Mosser sheath is a close copy of the Southern Saddlery, closer than a mid to late 1943 vintage Heiser. This is supported by the fact that the keeper location has dropped down by the throat of the sheath from the higher location found only on the earliest Heiser’s and of course Clarence Moore models.

In reading the interview in Rhett’s article, one question is raised and the answer still remains unclear, and that is, what exactly was the level of Northampton’s involvement? Packard Larsen states occasionally one of his sisters picked up blades from North Hampton Cutlery. William Larsen then assembled some of them in his basement, had barrels of leather washers, yet the final finishing was done at Northampton. One thing that does seem to remain somewhat consistent in the Springfield’s and that is the handles. Generally, they are of decent finish.

It is the blades and often spacers that show the major differences between what we consider a Northampton or something else. Gaddis states several times that the forger(s) was someone other than Northampton.

Gaddis also states Larsen initially had little success enlisting a cutlery company to do the entire job of fabrication, but organized several smaller companies to do specific portions of the work. Larsen never told Bo in his letters who those companies were, nor did he say who was doing the final assembly and handle shaping work.

So was Northampton used for initial grinding and final finishing with Larsen and perhaps some moon lighters doing all the assembly? Possibly. Did Northampton actually take rough forgings and complete the knives from that point? According to Gaddis, the answer is yes. I believe it was a combination of these and other scenarios with Larsen getting done what he could when he could, and sometimes by whomever including himself. After reading and analyzing numerous times what Bob Gaddis wrote about the Springfield saga in his book, I think much of the speculation that has been floating around for years was unwarranted and already explained.

I don’t know if we will ever know 100% for sure how this whole thing went down, but in reviewing older as well as more recent information, I think that a reasonable conclusion can be made.

The photos above are of the actual knife Bo Randall sent to William F. Larsen on 20 May 1943, to be used as a pattern for the Springfield Randall. Notice this example of a classic WWII blade grind from 1943, with a visible hump and a slightly slender blade on this particular knife. Although there was a broad range of blade shapes during the period, particularly earlier in the war, this is what most collectors would identify with the time.

The hilt is nice and thick and is of the brass of the time, brass sometimes being a tough material for Bo to acquire during WWII. The handle is typical as are the spacers. The butt is of a better quality than the earlier cast butts and probably machined from a sheet of aluminum. A brass nut and washer holds it all together. A monel wrist thong link tops it off.

The sheath is in near mint condition and is a South Saddelry model with the correct and mint Lily White Washita stone in the pocket.

Aside from the supreme historical importance of this piece, condition wise it is about as fine of an example of a WWII fighter you can find with only a very, very slight evidence of sharpening.